- Plastic fan

- FRP fan

- Stainless steel fan

- Plastic acid mist purif

- FRP acid mist purificat

- Stainless steel tower

- Horizontal cross spray

- Activated carbon absorb

- Activated carbon fiber

- Organic waste gas purif

- Chemical waste gas puri

- Electroplating waste ga

- Painting (coating) wast...

- Electrophoresis paint e...

- Plastic granulation exh

- Rubber exhaust gas puri

- Ammonia gas purificatio

- Casting exhaust gas pur

- Deodorization purificat

- Cartridge type dust col

- Cyclone separator

- Pulsed jet cloth filter

- Dust-containing cycloni

- Water film dust catcher

- Ion-exchange water puri

- Reverse osmosis water p

- Hollow fiber membrane u...

- Waste incinerator

- Photolysis exhaust puri

- Catering fume purifier

- Waste gas purification ...

- By-product hydrochloric

- Purification equipment ...

- Corrosive solution filt

- Venturi jet device

- FRP septic tank

- Aerator, drainage cap,

- Environmental protectio

- Activated carbon, carbo...

- Plastic pipeline, pipe ...

- Plastic air pipe, air v...

- Corrosion prevention of...

- Plastic reaction kettle

- Plastic mixing tank

- Plastic tank

- Plastic vacuum metering

- Plastic vacuum suction

- FRP tank

- Plastic/FRP composite t

- Graphite modified polyp...

- Graphite modified PP tu...

- Stainless steel tower

- Stainless steel centrif

- Stainless steel tank

- Stainless steel reactor

- Stainless steel mixing

- Stainless steel heat ex

- Stainless steel drying

- Stainless steel ferment

- Automatic hanging-plati

- Automatic barrel-platin

- Spoke electroplating eq

- Semi-automatic barrel p

- Manual barrel plating e

- Manual hanging-plating

- Electroplating solution

- Electroplating power su

- Electroplating auxiliar

- Reinforced polypropylen

- All plastic water jet v

- Metal water jet vacuum

- Metal water jet vacuum

- Stainless steel water j

- Steam-water series wate

- Roots-water jet vacuum

- Water jet condensing pu

- Building drainage vacuu

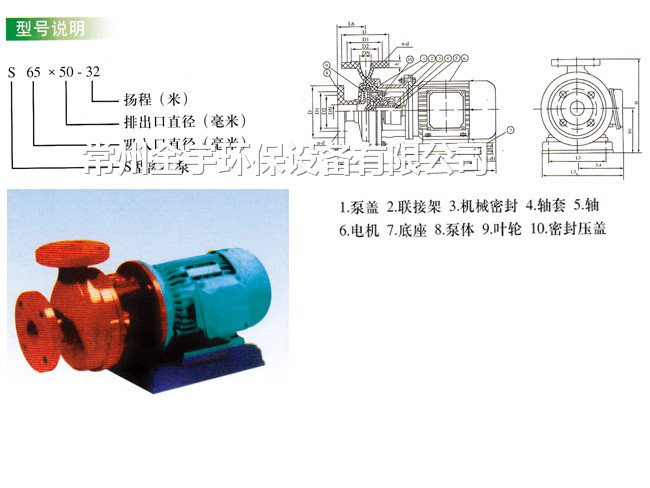

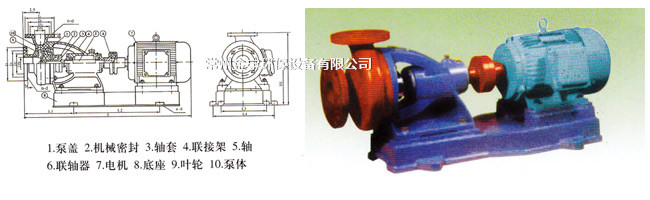

FRP anti-corrosive pump

Dimensions and installation dimensions:

|

Models

|

Suction inlet

|

Discharge port

|

L

|

L1

|

L2

|

L3

|

L4

|

L5

|

L6

|

H

|

H1

|

H2

|

n1

|

d1

|

Motor power(kw)

|

||||||||||||

|

DN

|

D

|

D1

|

D2

|

b

|

n

|

d

|

DN

|

D

|

D1

|

D2

|

b

|

n

|

d

|

||||||||||||||

|

S25×25-12.5

|

25

|

115

|

85

|

65

|

16

|

4

|

14

|

25

|

115

|

85

|

65

|

16

|

4

|

14

|

437

|

180

|

180

|

140

|

150

|

244

|

60

|

200

|

94

|

23

|

4

|

14

|

0.75

|

|

S40×32-20

|

40

|

145

|

110

|

88

|

18

|

4

|

18

|

32

|

135

|

100

|

78

|

18

|

4

|

18

|

458

|

192

|

200

|

150

|

150

|

252

|

82

|

258

|

120

|

40

|

4

|

18

|

1.1

|

|

S40×32-32

|

40

|

145

|

110

|

88

|

18

|

4

|

18

|

32

|

138

|

100

|

78

|

18

|

4

|

18

|

540

|

230

|

240

|

160

|

155

|

262

|

85

|

315

|

145

|

55

|

4

|

18

|

2.2

|

|

S50×40-20

|

50

|

160

|

125

|

100

|

20

|

4

|

18

|

40

|

145

|

110

|

88

|

19

|

4

|

19

|

535

|

226

|

240

|

160

|

155

|

262

|

100

|

295

|

145

|

55

|

4

|

18

|

2.2

|

Dimensions and installation dimensions:

|

Models

|

Suction inlet

|

Discharge port

|

L

|

L1

|

L2

|

L3

|

L4

|

L5

|

H

|

H1

|

n1

|

d1

|

power(kw)

|

||||||||||||

|

DN

|

D

|

D1

|

D2

|

b

|

n

|

d

|

DN

|

D

|

D1

|

D2

|

b

|

n

|

d

|

||||||||||||

|

S50×32-32

|

50

|

160

|

125

|

100

|

18

|

4

|

18

|

32

|

135

|

100

|

75

|

18

|

4

|

18

|

945

|

319

|

420

|

310

|

370

|

80

|

435

|

250

|

4

|

24

|

4

|

|

S65×50-20

|

65

|

180

|

145

|

120

|

21.5

|

4

|

18

|

50

|

160

|

125

|

100

|

21.5

|

4

|

18

|

830

|

250

|

420

|

250

|

320

|

90

|

360

|

210

|

4

|

18.5

|

3

|

|

S65×50-32

|

65

|

185

|

145

|

122

|

22

|

4

|

18

|

50

|

165

|

125

|

102

|

22

|

4

|

18

|

1020

|

345

|

420

|

310

|

370

|

90

|

430

|

250

|

4

|

24

|

5.5

|

|

S80×65-32

|

80

|

195

|

160

|

135

|

23.5

|

4

|

18

|

65

|

180

|

145

|

120

|

21.5

|

4

|

18

|

1022

|

370

|

520

|

310

|

410

|

100

|

450

|

250

|

4

|

24

|

7.5

|

|

S80×65-32

|

80

|

195

|

160

|

135

|

23.5

|

4

|

18

|

65

|

180

|

145

|

120

|

21.5

|

4

|

18

|

1150

|

370

|

520

|

310

|

410

|

100

|

480

|

250

|

4

|

24

|

11

|

|

S100×80-50

|

100

|

215

|

180

|

158

|

24

|

8

|

18

|

80

|

195

|

160

|

138

|

23.5

|

4

|

18

|

1353

|

428

|

635

|

370

|

485

|

110

|

530/ 575

|

280/ 300

|

4

|

24

|

Y168L/ Y200L-22/30

|